- Test smarter, not harder. Choose TestPlanner

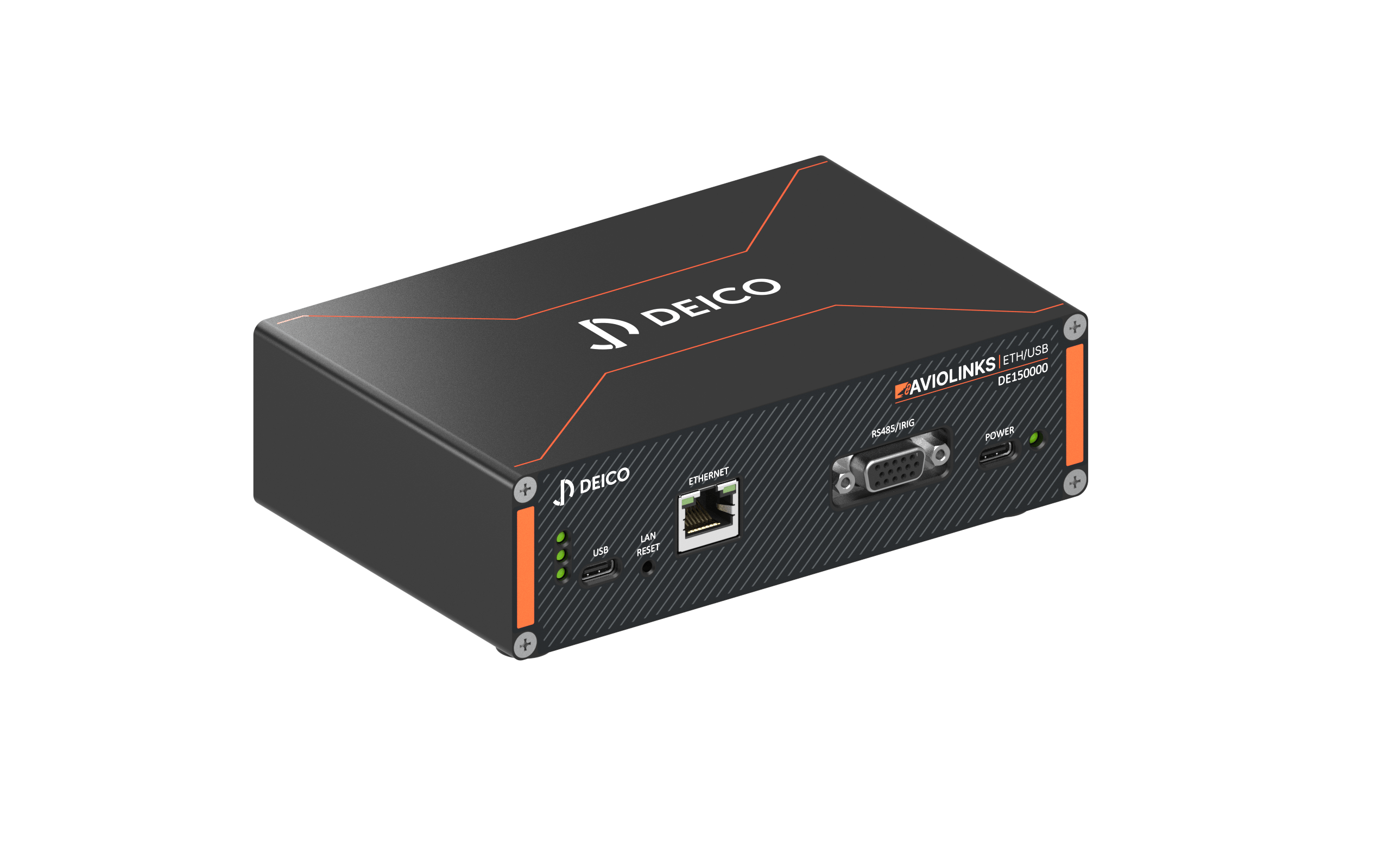

USB/Ethernet Converter Products

- DEICO offers a complete range for sub products to get the best performance.

Battery Management System (BMS) Test Products

- Battery test products are safe, efficient, and accurate simulation products for new storage technologies.

- These products are equipped with advanced features.

- Advanced video switching and distribution solutions.

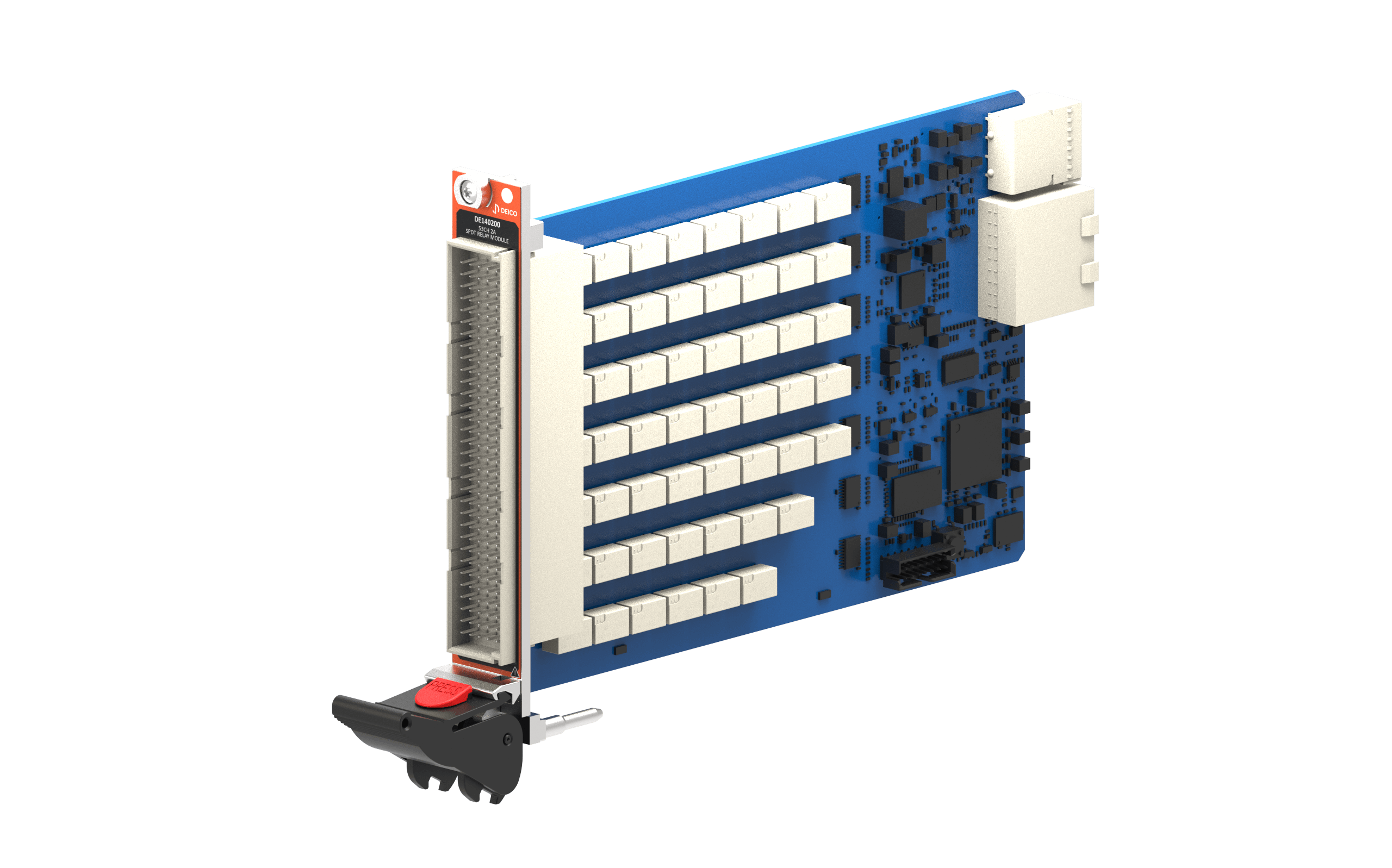

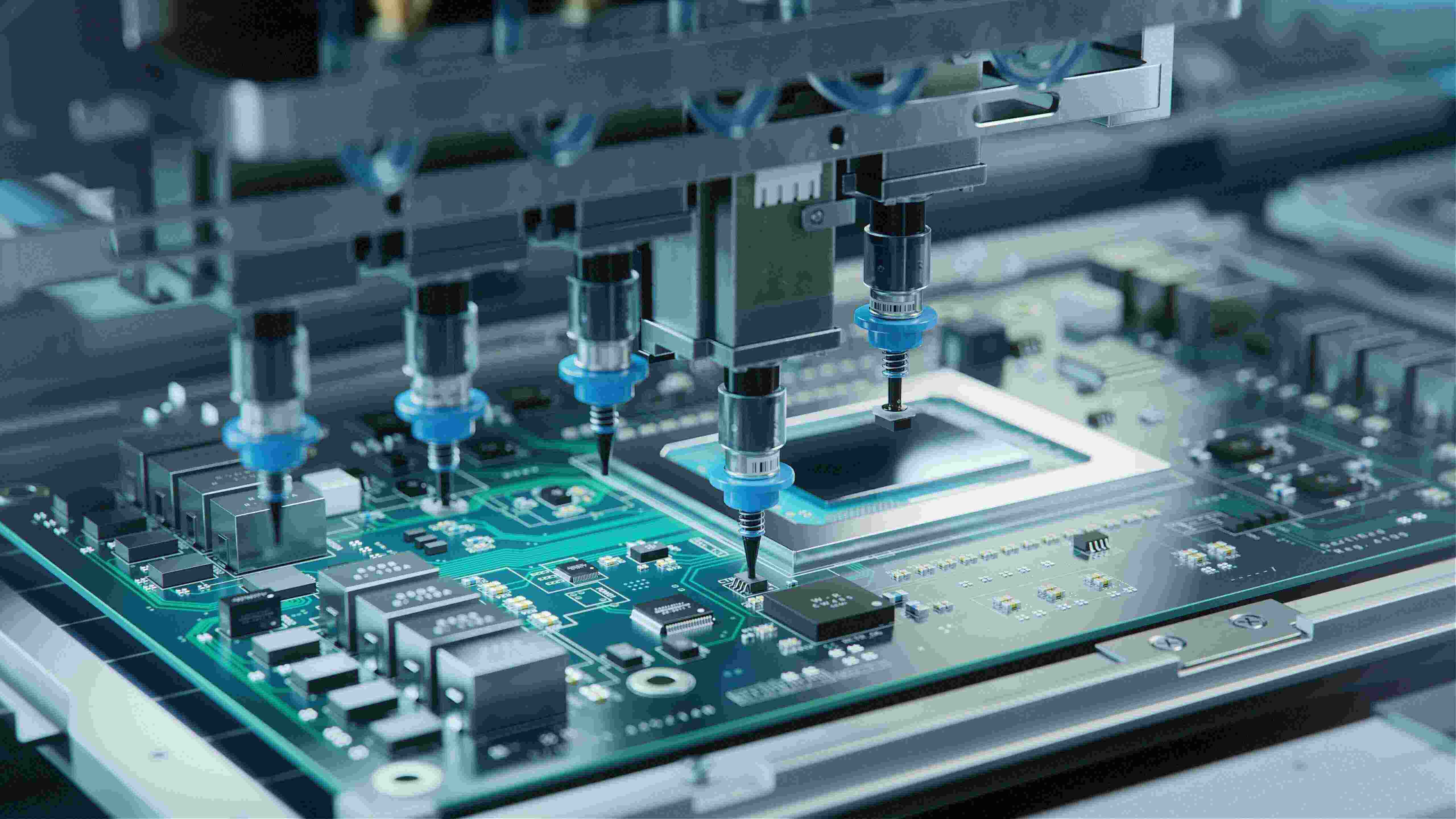

- DEICO ensures high testing capacity for advanced board designs.

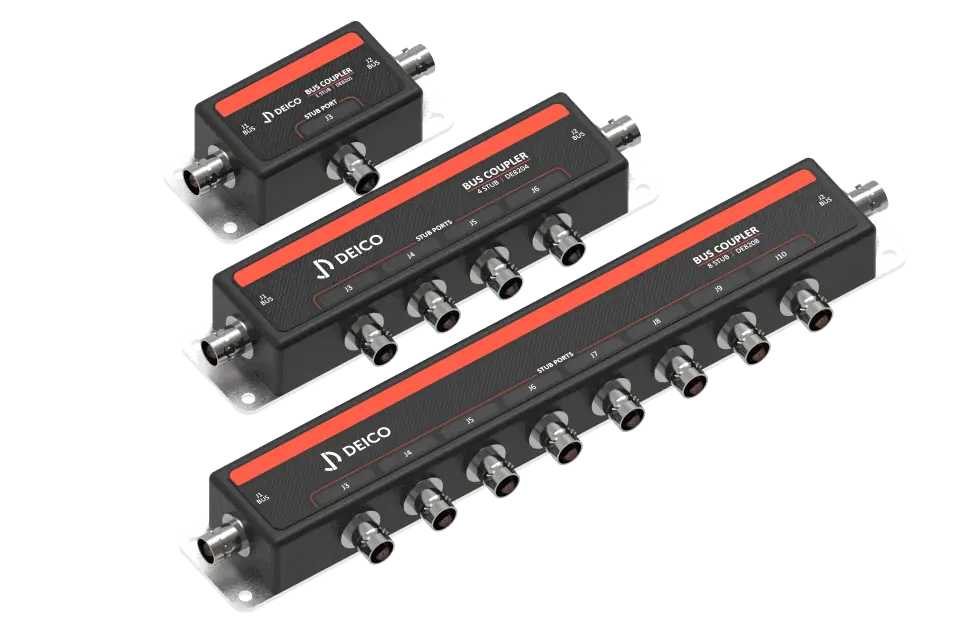

- DEICO offers diverse bus couplers to customer needs.

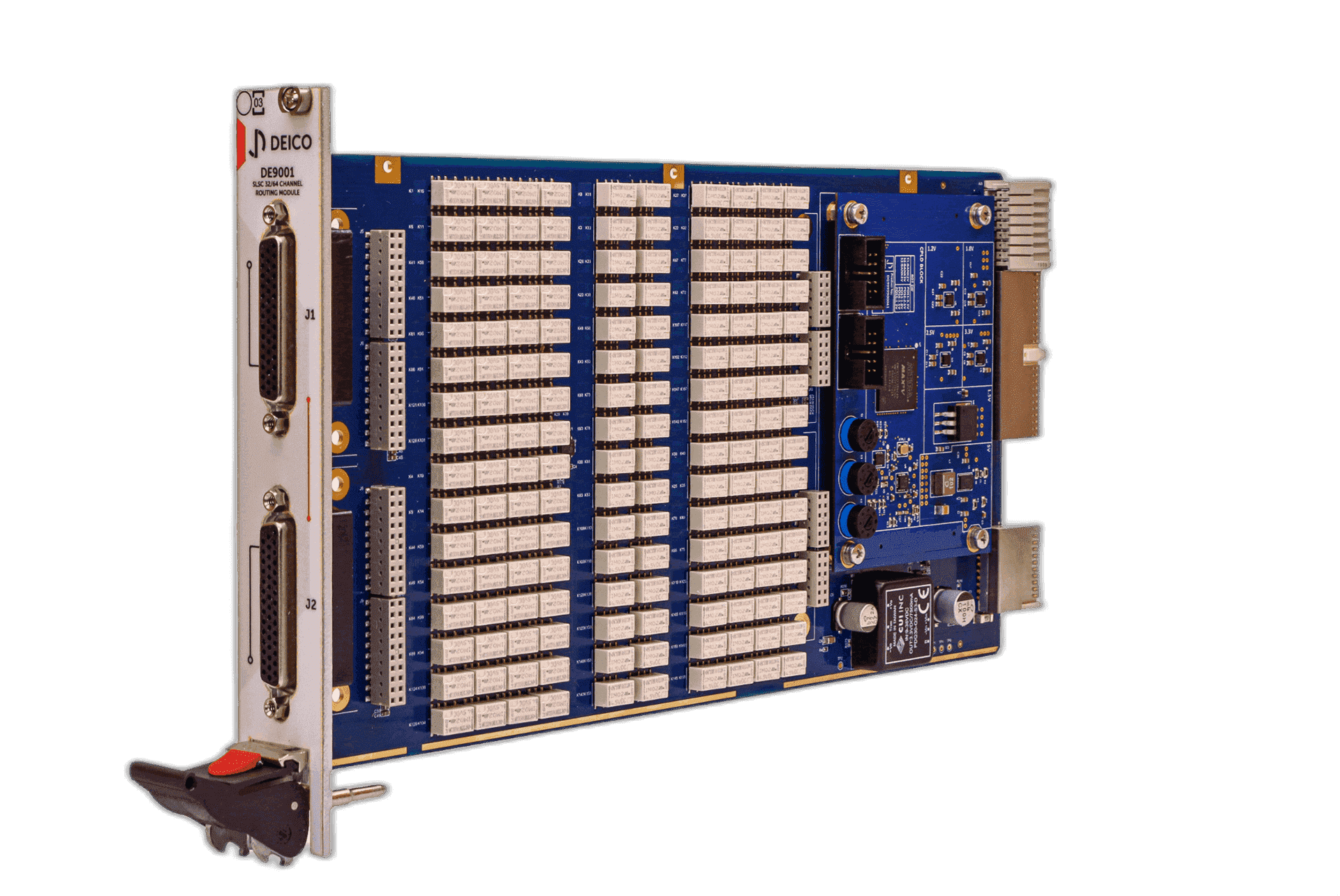

- SLSC reduces the time spent on common needs in test systems.

- These systems ensure reliability across diverse mission scenarios.

- DEICO's PXIe Systems offer comprehensive modular solutions for diverse industries.

Switching & Data Acquisition Systems

- All test systems need data acquisition structures to collect and analyze data.

- This series offers a wide range of test and measurement equipment products.

- JTAG Technologies is boundary-scan.

- DEICO avionics devices offer reliable, standard-compliant testing solutions.

TestPlanner

TestPlanner is a test automation software designed to help hardware test enginee..