Test Configuration for Design Verification of Mission Computers

Yusuf Yıldırım, Hayati Cem Atakan, Mert Değerli

Abstract – This study shows a different approach for mission computer testing. The standard procedure of testing mission computers consists of the design of the wiring set and the interface adaptor. The overall system can be partitioned into three blocks, namely; the mission computer (DUT), the interface adaptor, and the test computer. In order to test different mission computers with different wiring interfaces, the interface adaptor and the wiring between these blocks need to be updated for each mission computer. In this study, a generic, computer-aided and modular test configuration is proposed as a solution to the design verification tests of mission computers. The test computer is prepared on PXI chassis with all required communication ports (RS-422, RS-232, Ethernet, CAN, 1553). In addition, some required modules are added, such as a relay module, a multiplexer module, and a DMM module. A VPC G18 receiver is also combined with the test computer via some mechanical parts. A custom design interface box is the last part of the hardware. The software part is developed in C-sharp and is used mainly for automated tests. However, it is also possible to be used in some manually configured, operator-driven tests. The proposed test configuration provides a number of improvements compared to the existing test configurations. Reduced test preparation time, reduced engineering support for test preparation, reduced price, and reduced failure rate are some of the major improvements of the proposed system. This configuration is implemented and used on various mission computers that are deployed on various systems on different platforms.

Keywords – Design verification testing, test configuration, automatic test system, PXI, mission computer

1. INTRODUCTION

Many people hold the testing of products in the same regard as the actual design. In fact, many development projects specify Design Validation Testing (DVT) as a major contract requirement.

DVT, an intensive testing program, is a critical step in the path of ensuring a successful product. Characterizing and validating a Device Under Test (DUT) will focus on acquiring many vectors (voltage, power, frequency, etc.) across multiple scenarios, generating large volumes of data for analysis. DVT consists of the following areas of testing:

- Functional testing: Testing the requirements that are determined in the design process with test scenarios. The test not only includes real-world simulations, but also, for some DUTs, it may include some simulations that can be out of real-world to debug unexpected errors.

- Performance testing: The test involves the functional tests; but the difference is that instead of testing the requirements one by one, all the requirements are tested together by pushing their limits.

- Environmental test: DUT is tested for the environmental requirements.

- Electromagnetic interference/compatibility (EMI/EMC) test: DUT is tested within standard which is a standardization that checks the electromagnetic emission of DUT and its influence on DUT when the specified electromagnetic emissions are applied.

Test station development for mission computers has historically relied on custom point solutions. The technological advancements in commercial-off-the-shelf (COTS), industry-standard equipment coupled with a software-driven design provided the opportunity to develop a Universal Test Station (UTS) that can be utilized for various instruments. The UTS exploits the PXI architecture to facilitate the integration of modular instrumentation and to provide test stimulus, measurement capability. This design is composed of:

- Scalable Base Station for hosting interchangeable hardware components specifically selected to satisfy the requirements of the particular Unit Under Test (UUT).

- Standardized software architecture for executing test sequences, collecting and analyzing data, detecting errors and fault conditions, and providing a graphical user interface

(GUI).

- Interface Test Adapters (ITAs) for hosting the specialized functionality of a particular UUT.

2. EXTANT TEST SETUP

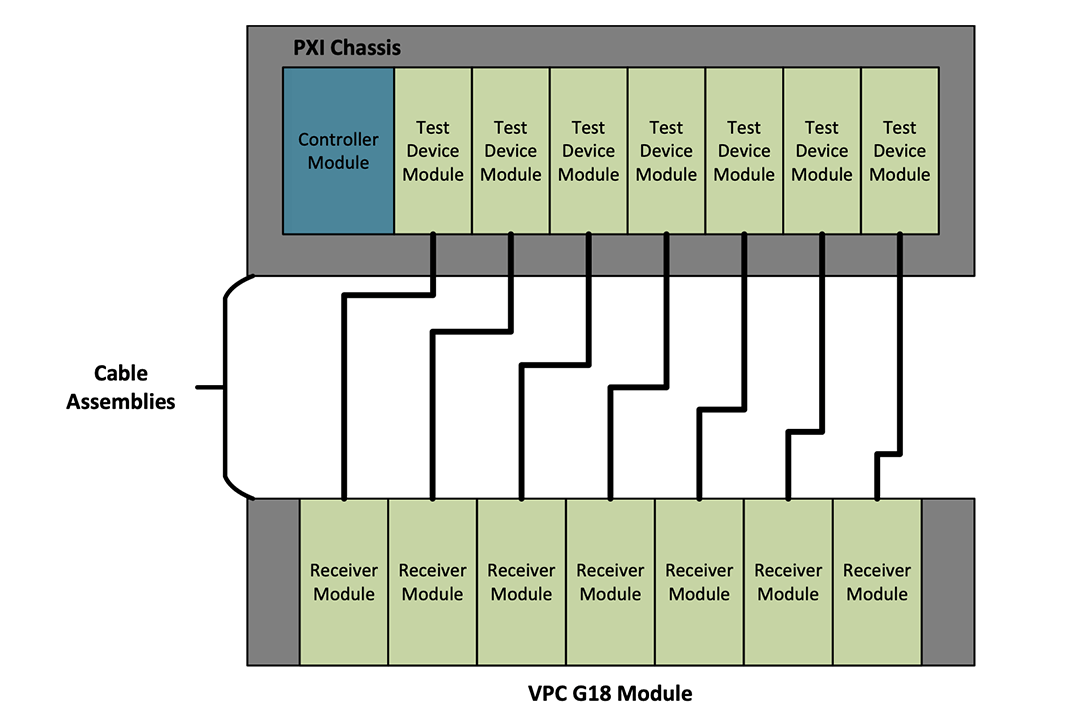

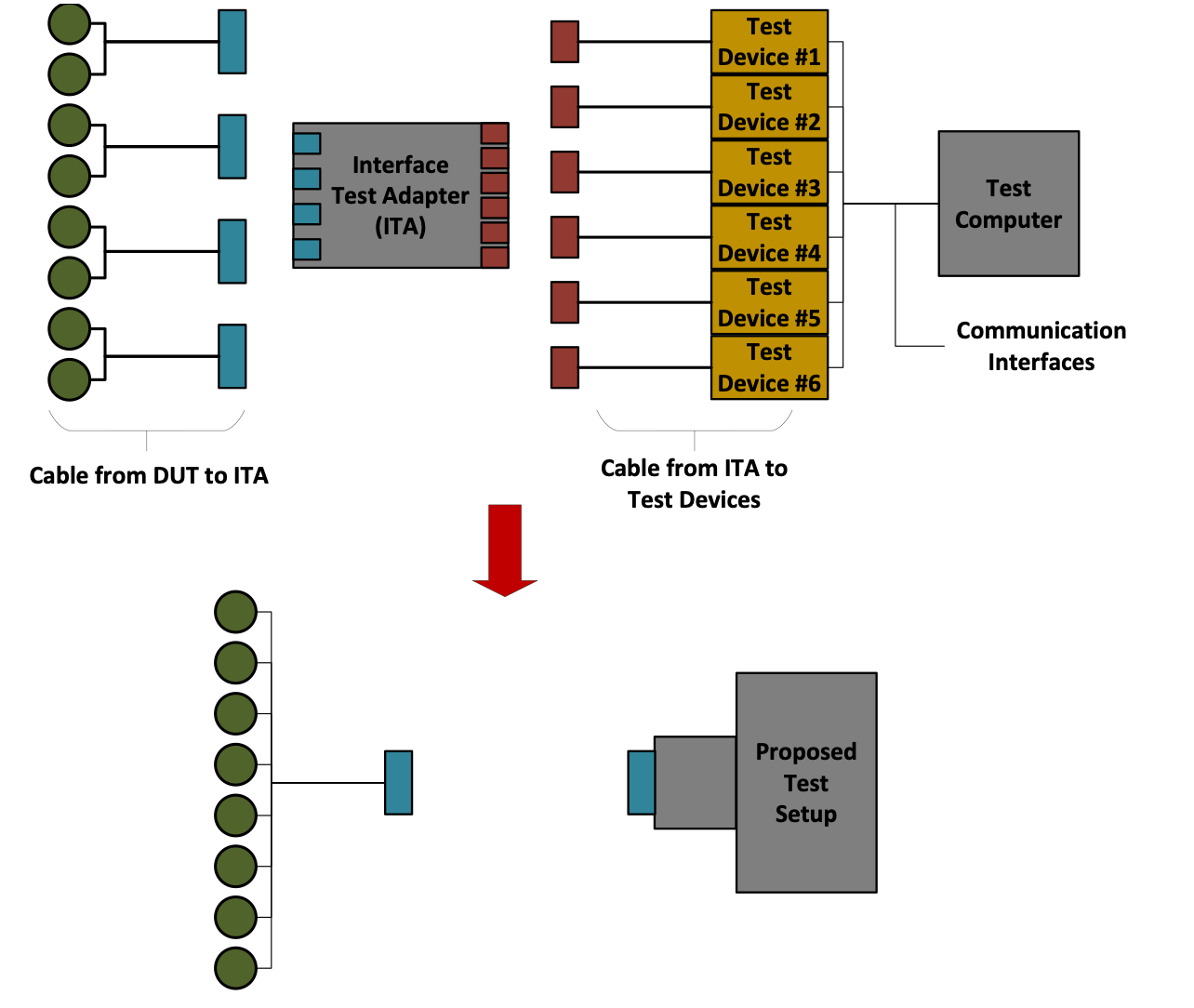

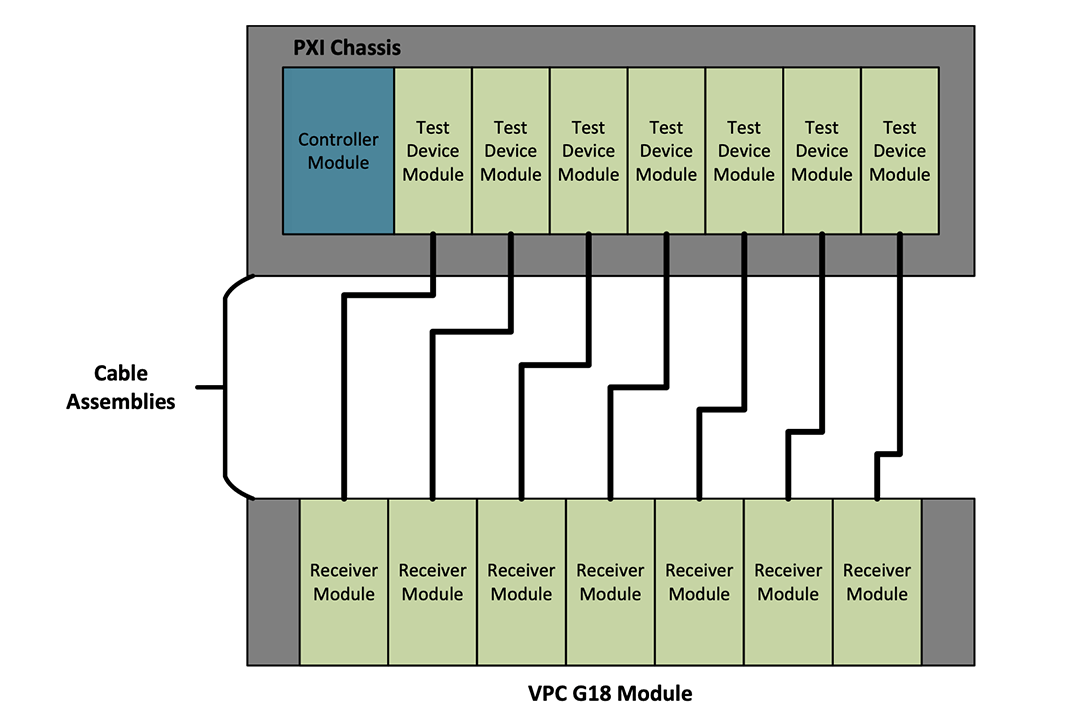

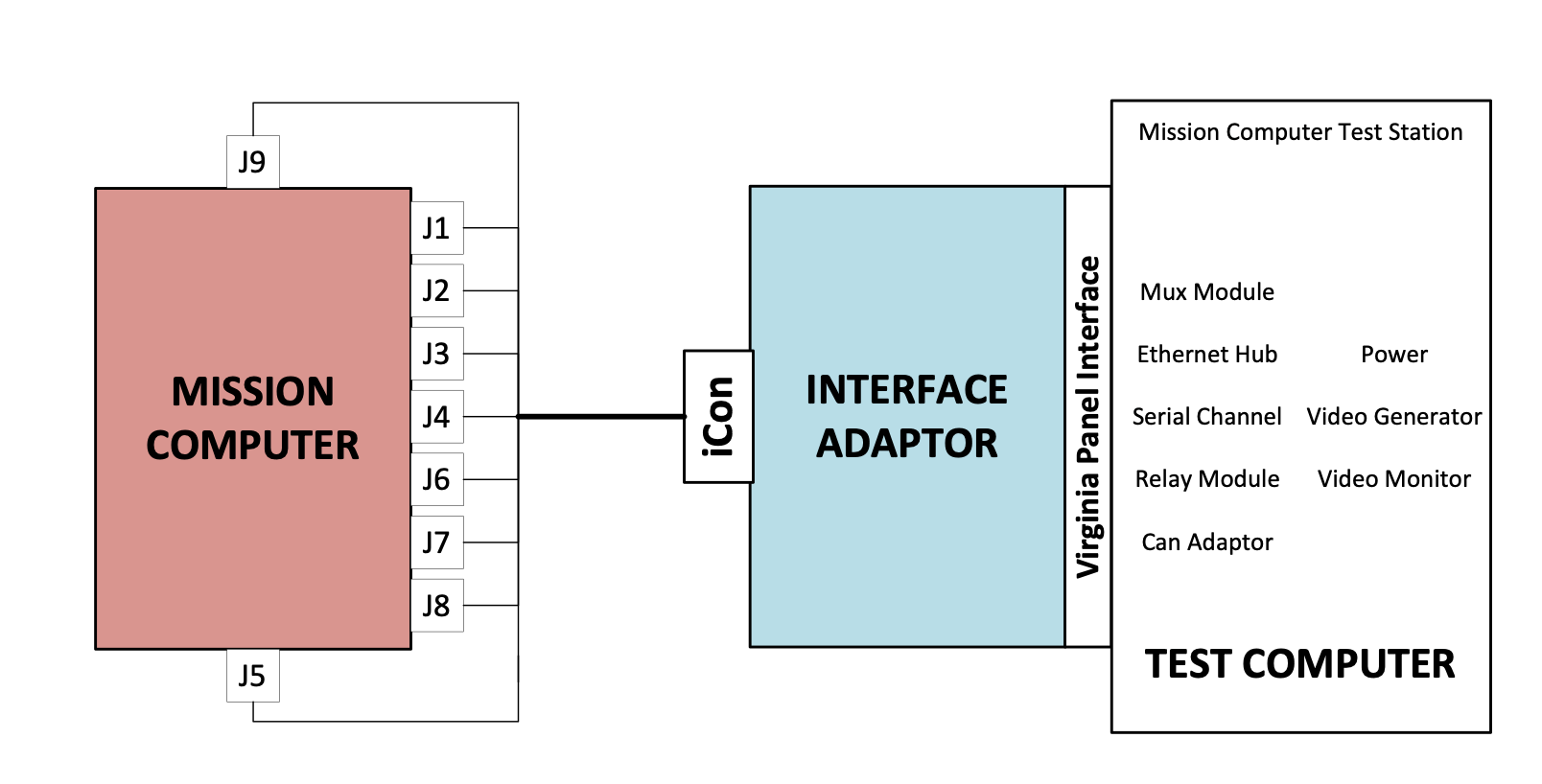

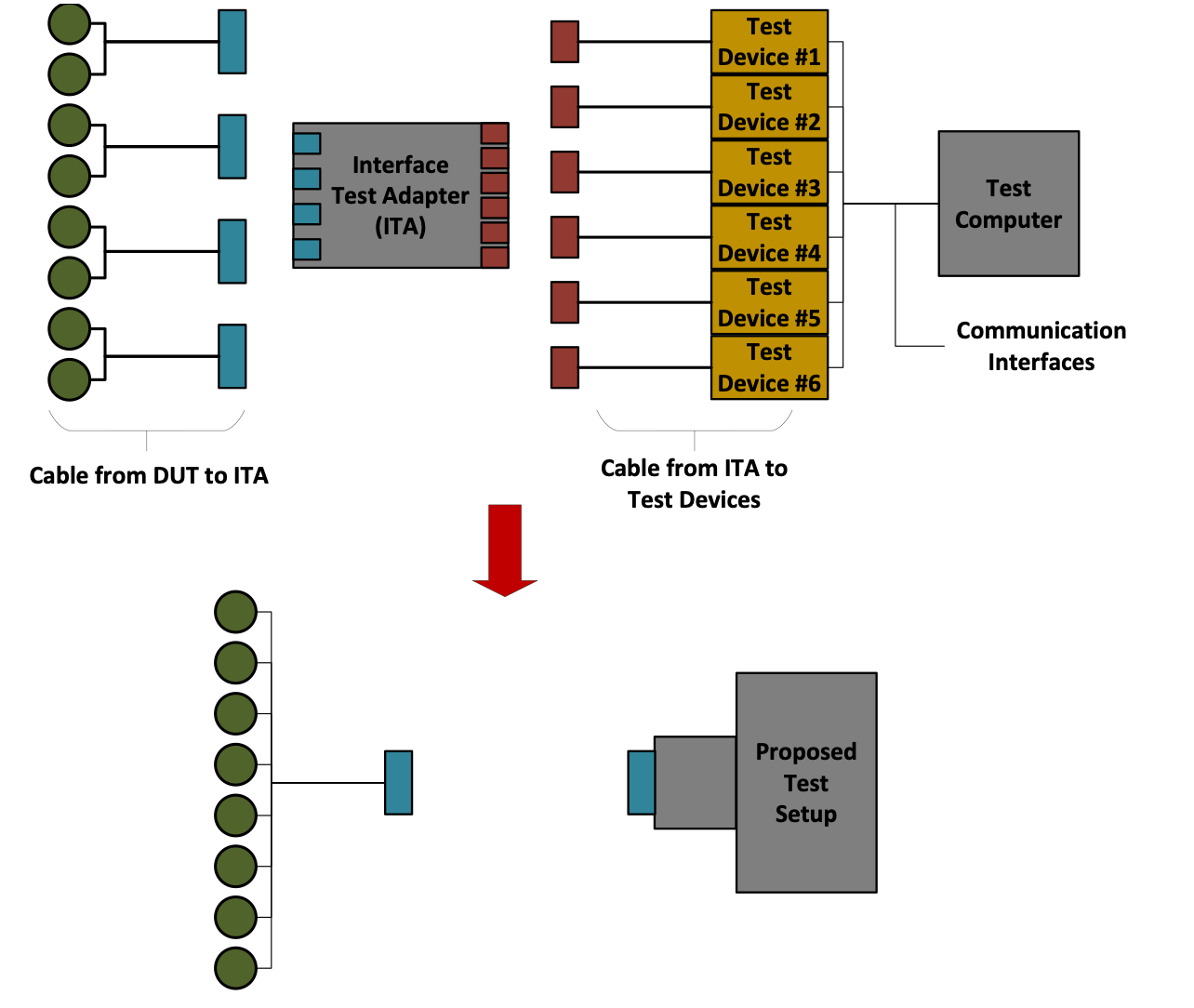

Throughout the history of DVT of mission computer in my experience, setup is created as is shown in Figure 1. Setup can be partitioned into 4 blocks, namely; cables between DUT and interface adaptor, interface adaptor, cables between interface adaptor and measurement devices, and measurement devices.

Figure 1-The Extant Setup

Cables from DUT to the interface adaptor are designed. Afterwards, the input ports of the interface adaptor are decided leading to its design. Output ports are defined. Finally cables between interface adaptor and test devices are connected. Related test devices are chosen for the setup. These test devices are connected to the test computer which will be used to control test process. Test scenario is prepared within the software, designed by the test engineer.

Finally setup is electrically ready for the functional tests. All 4 partitions belong to the specific DUT.

3. PROPOSED SETUP

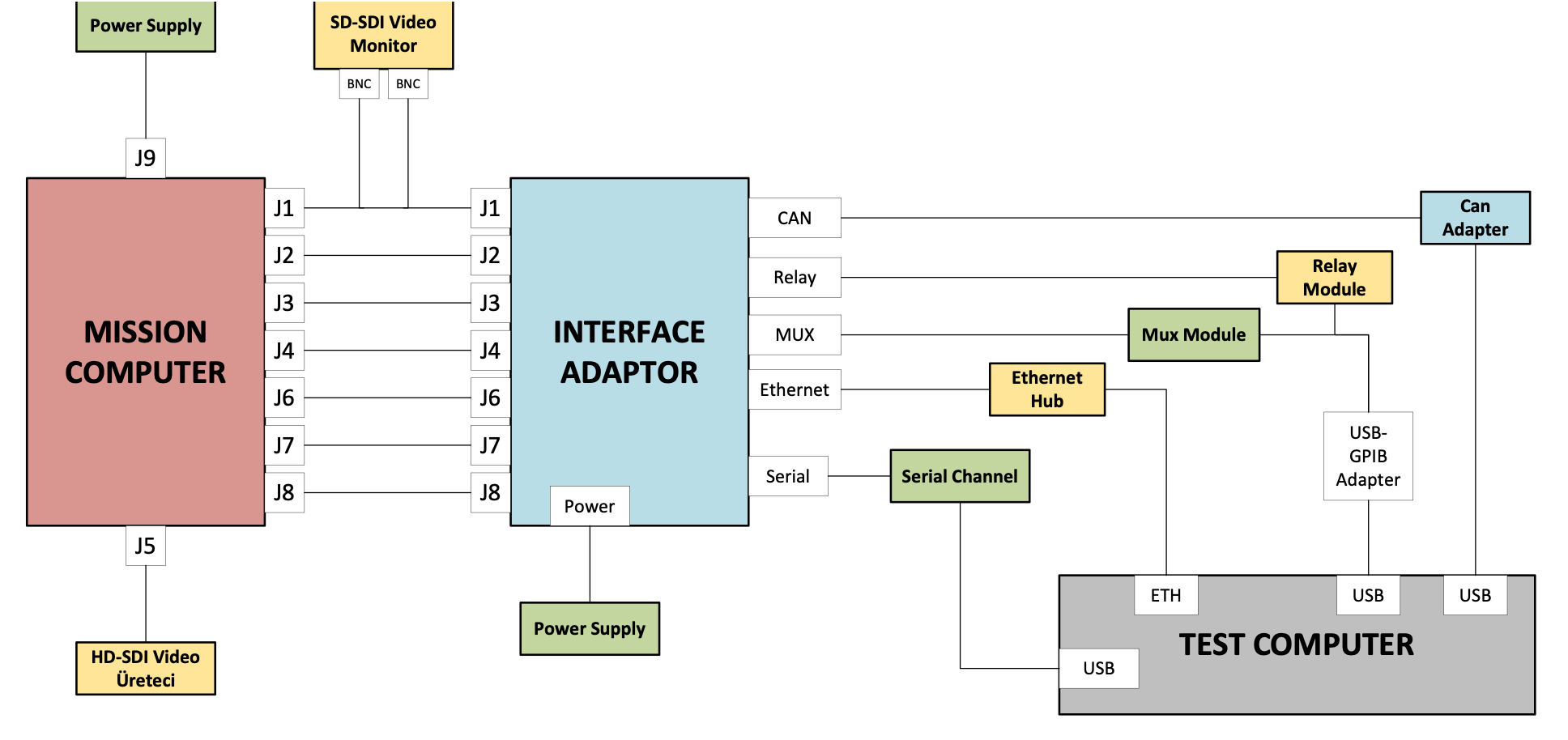

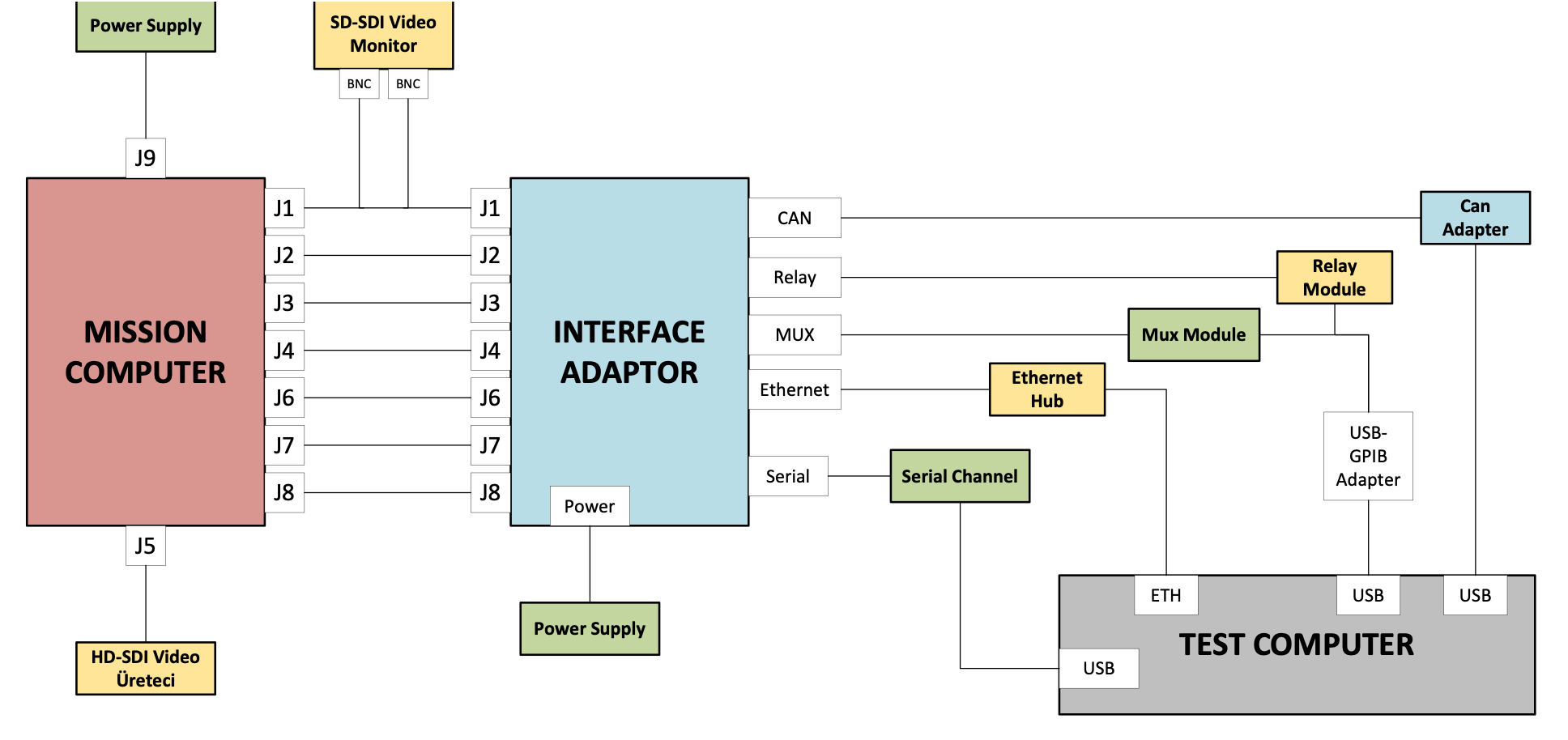

Since mission computers have more or less the same ports, standardization may work. The main idea behind this standardization is that reducing the connection needed for each mission computer by the same test setup. The test setup is basically as shown in Figure 2.

Figure 2-The Proposed Setup

Proposed setup can be partitioned in 2 blocks unlike the existing setup which has 4 blocks. The cable between DUT and interface adapter is designed to connect the outputs of DUT to test devices. The interface adapter is merged with test devices and test computer which is used to control them.

Within the standardization;

- The cable between interface adapter and test devices is removed

- The changes needed in the connections for each mission computer test setup are required to be made only once.

- The test software preparation time is reduced with the help of the software which is predesigned specifically for automated test.

4. TEST CONFIGURATION DESIGN AND IMPLEMENTATION

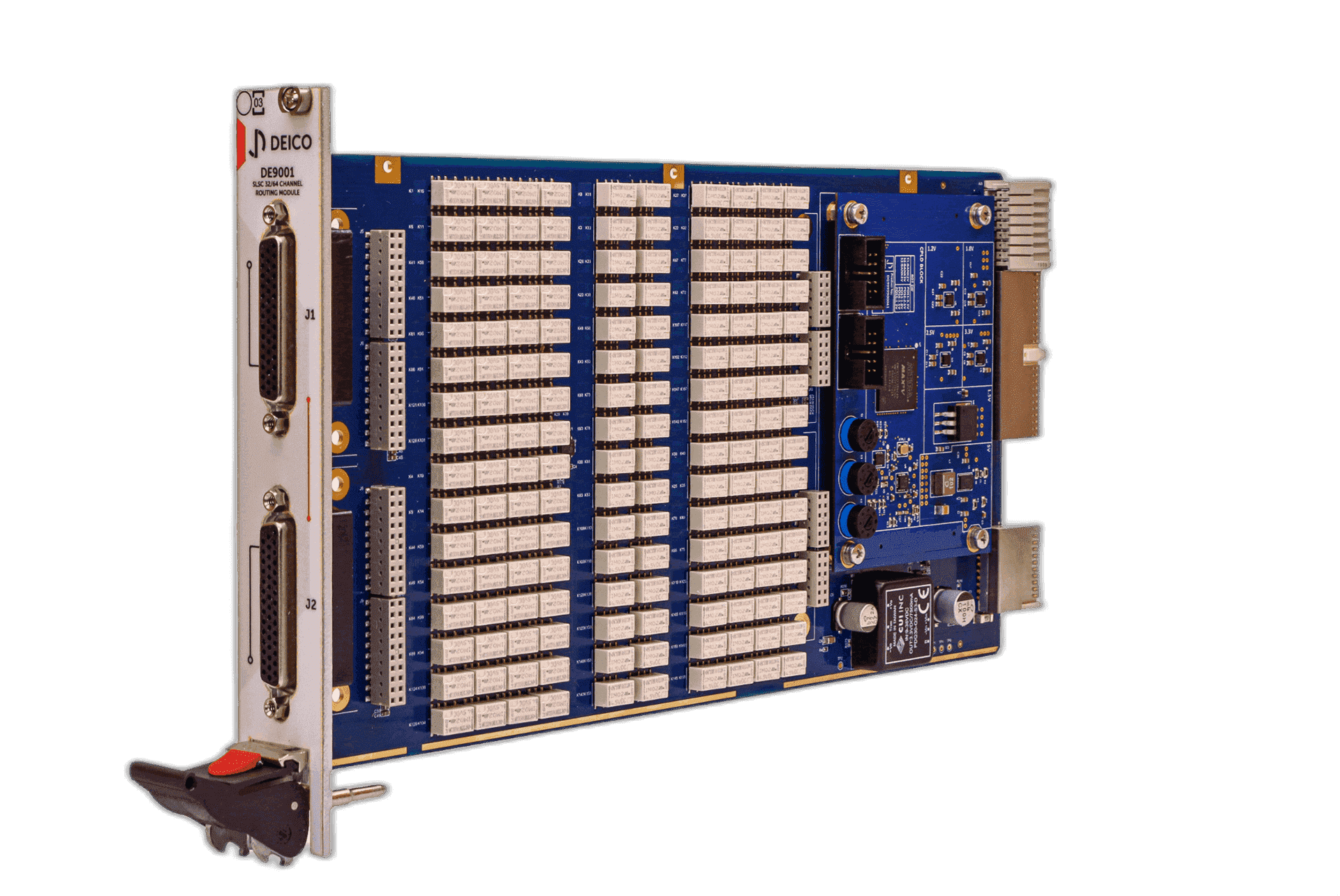

The test computer is prepared on PXI chassis with related modules;

- CAN communication

- RS232/ RS422/ RS485 communications

- MIL-STD-1553 communication

- Gigabit ethernet switches

- Digital I/O

- Relays

- Multiplexer

- DMM

- DC power supply

PXI Chassis with the above configuration is chosen specifically for mission computer test setup. The only module that is not on the chassis is the independent DC power supply to meet the high power requirements which might be needed.

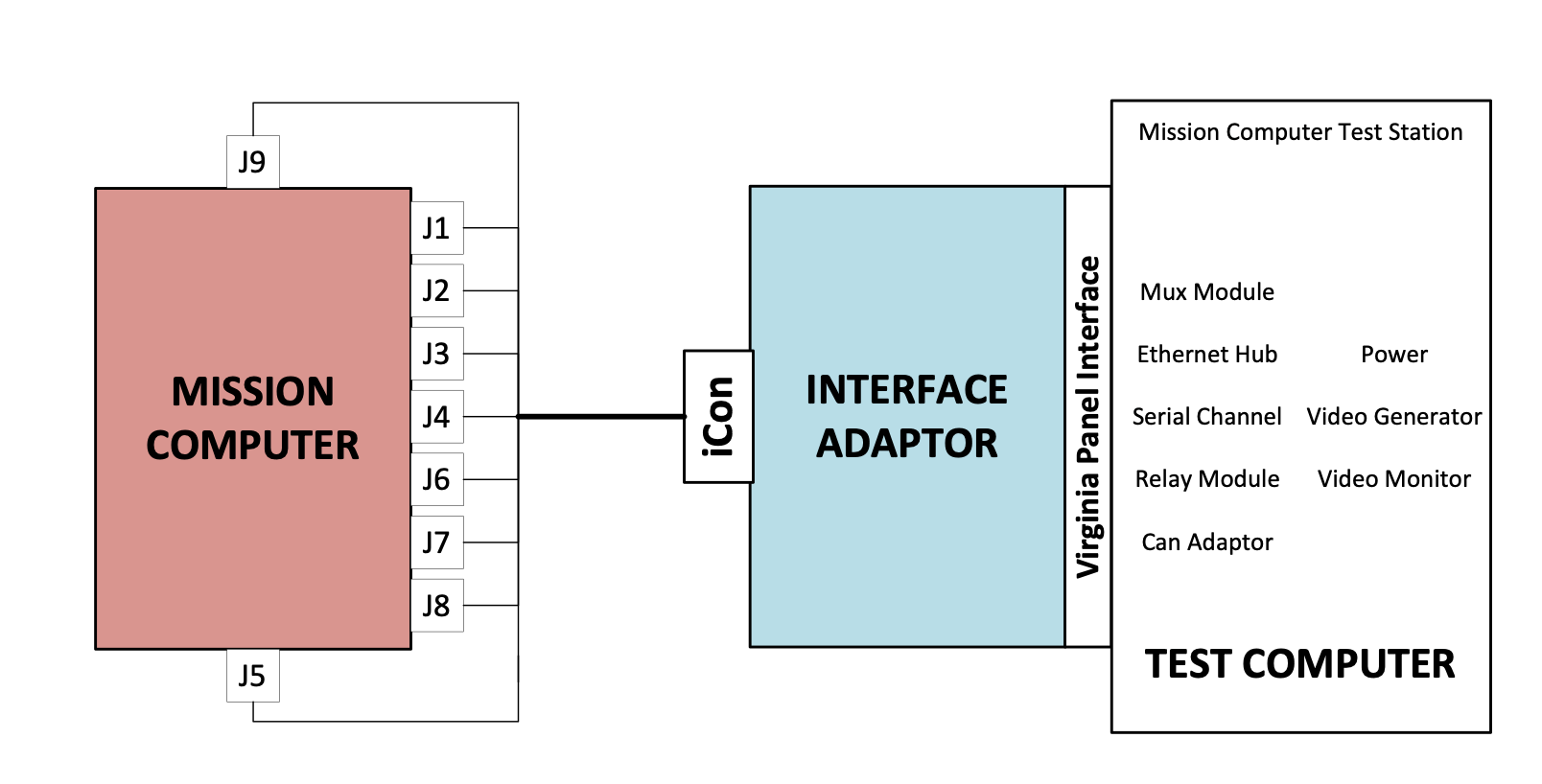

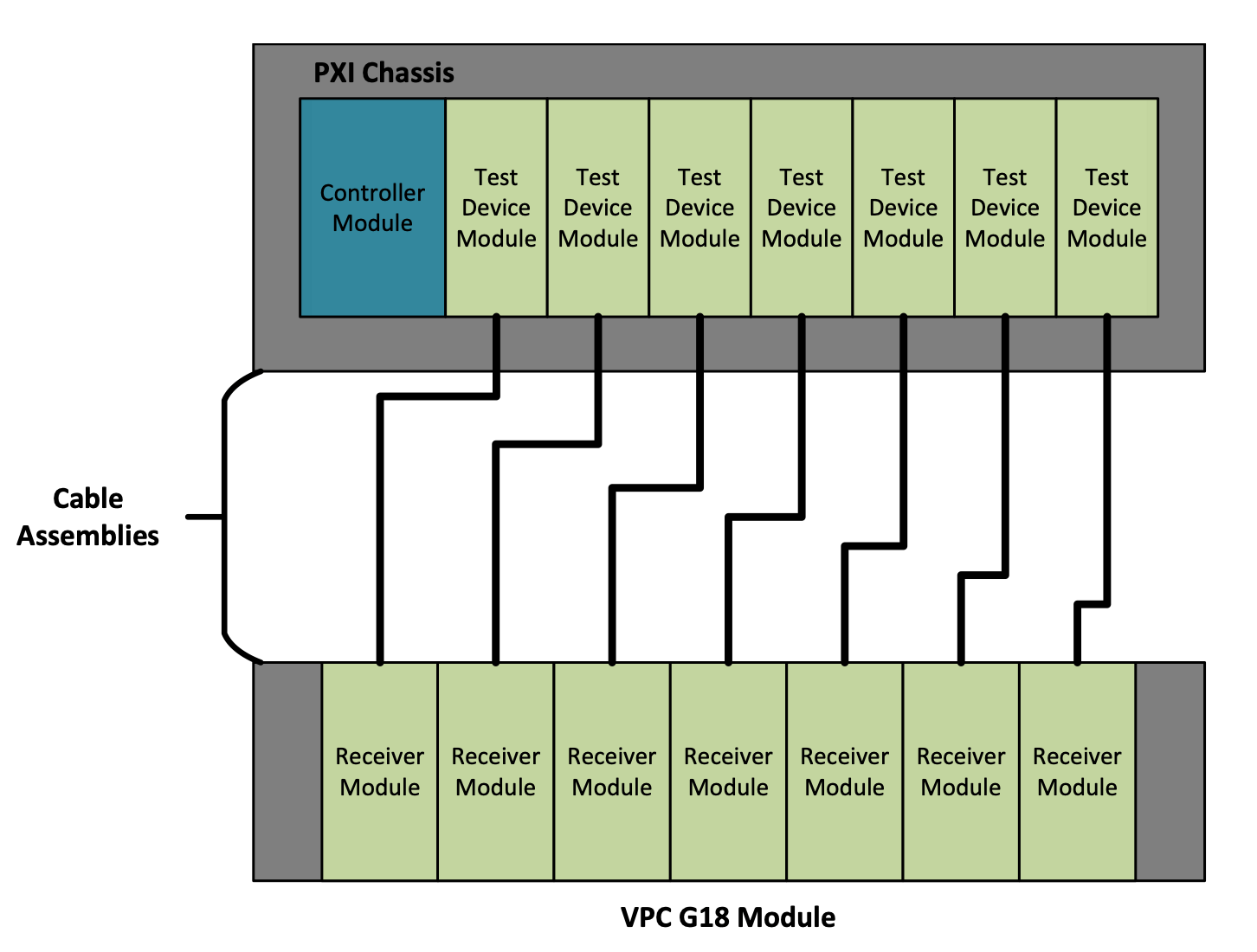

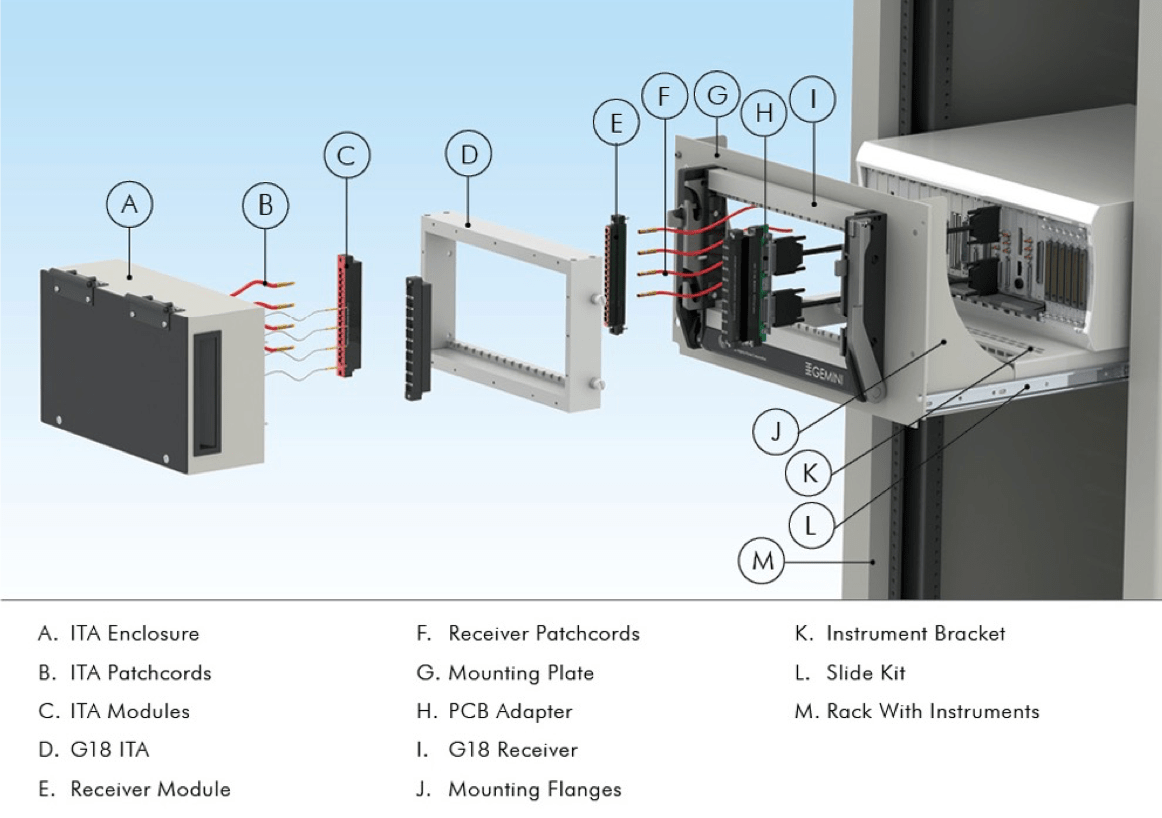

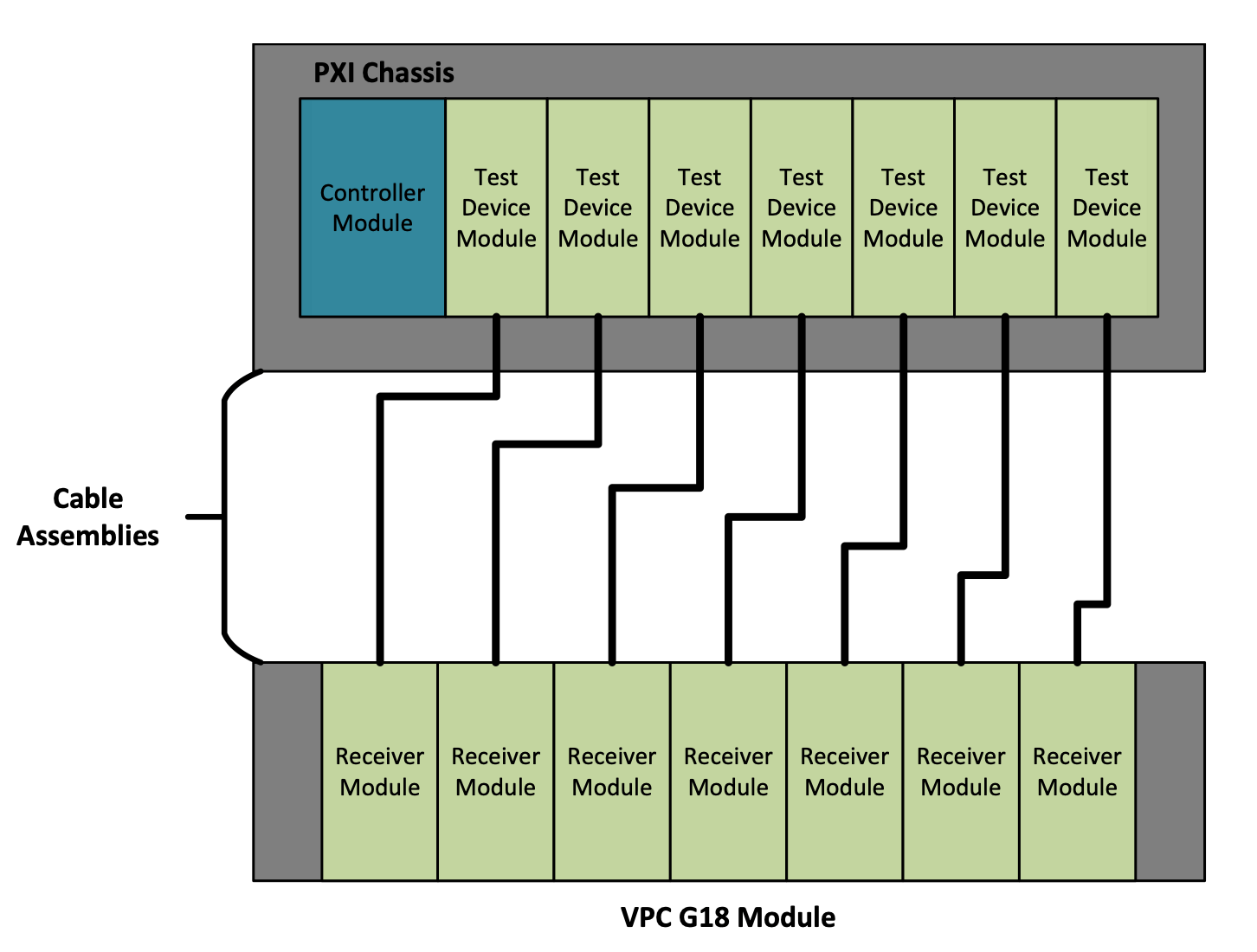

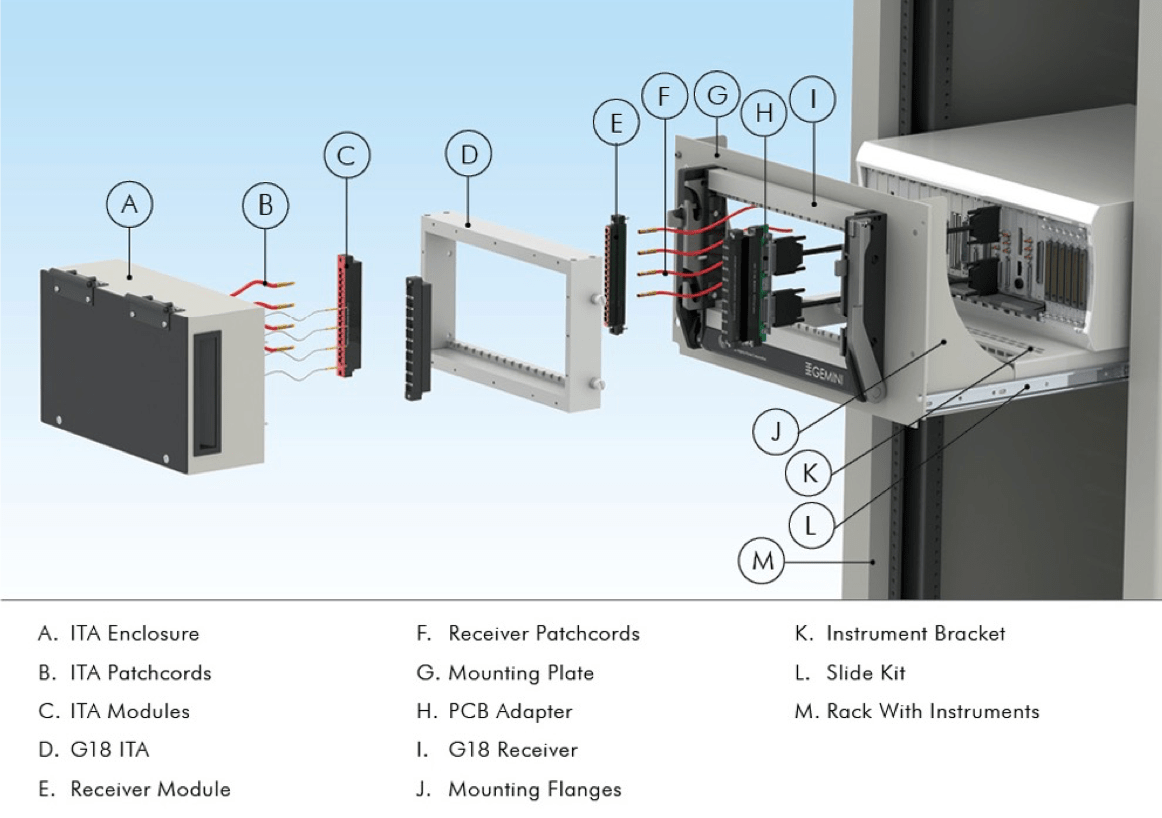

All these interfaces are linked to VPC G18 receiver by related cables with some mechanical parts. The structure can be shown in Figure 3.

Figure 3-PXI Chassis with VPC G18 Reveiver Structure

PXI Chassis with VPC G18 Receiver structure, independent DC power supply and 1U Rack LCD Monitor Keyboard Mouse Drawer are placed on a rack system. By the configuration, the test setup can be controlled easily by test operators and can be moved by the use of rack wheels.

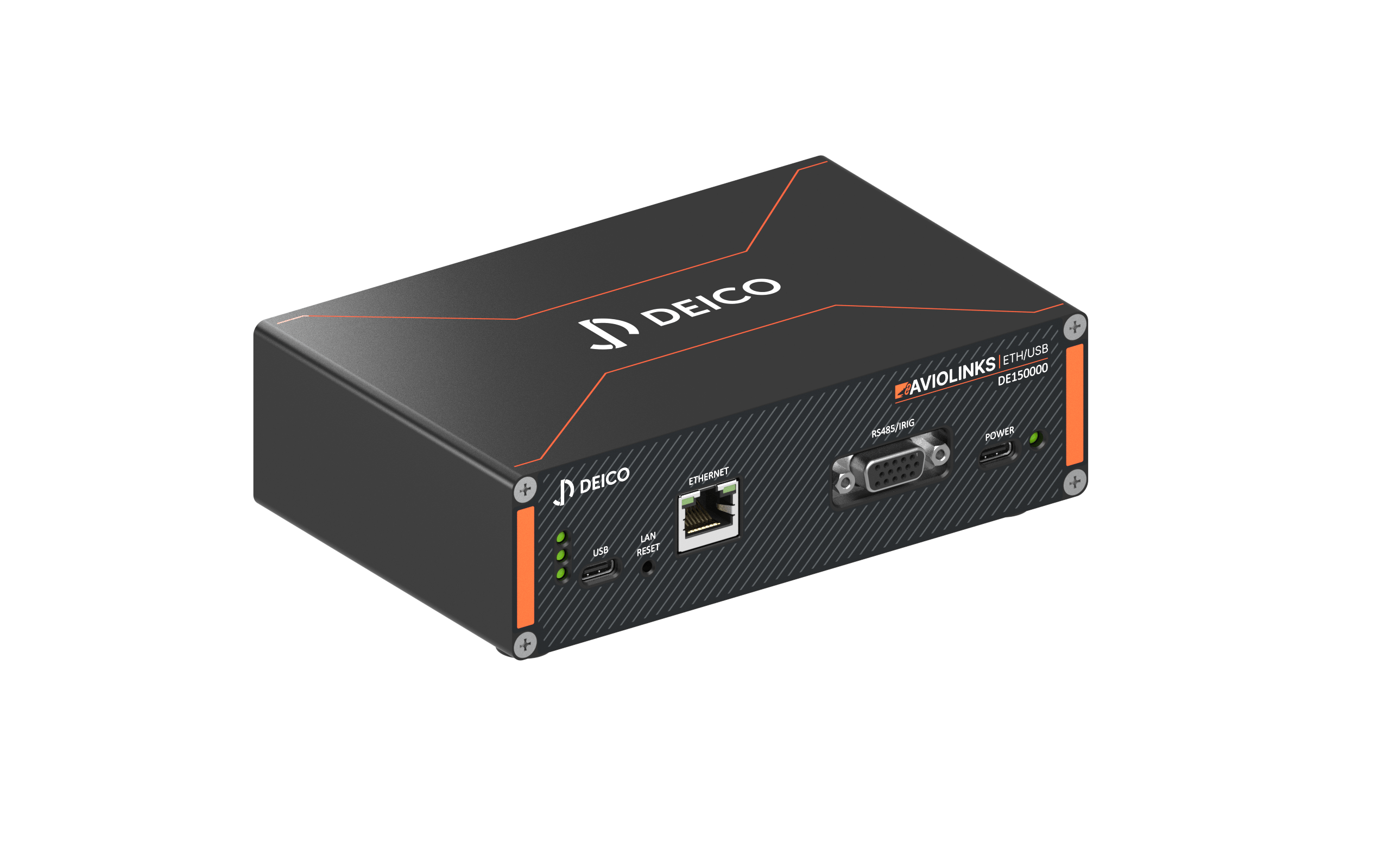

A custom design interface box is used as an adapter for connecting VPC G18 to iCon connector where iCon connector is the output of the whole test setup. This configuration merged the test computer, ITA and test devices in the test setup.

Figure 4-G18 Slide Configuration [6]

Within the configuration, each mission computer test setup can be electrically connected to the test setup by only one cable assembly.

The dynamic-link libraries (dll), coded on CSharp are prepared to control all PXI modules easily and gather test data from DUT. These modules are prepared by the help of the drivers given by manufacturers of test devices. Pre-designed software modules reduce the test preparation time.

One of the test setups is prepared with;

- Cable Assembly: All interfaces involving the output connectors of DUT(used as mission computer from now) are linked to test setup with iCon connector.

- Software: Pre-designed software modules (dlls) are combined with NI TestStand test management software to prepare test scenario.

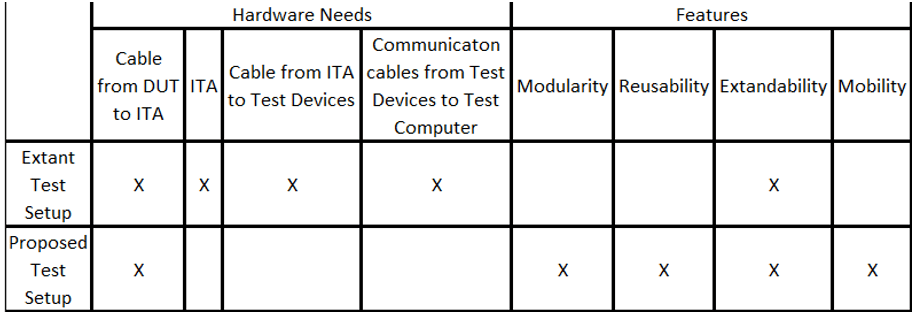

The structures would be needed for the extant test setup are given below:

- Three Cable Assembly:

- DUT to ITA: The output connectors of DUT are connected to the input connectors of ITA

- ITA to Test Devices: The output connectors of ITA are connected to the related interfaces of test devices

- Test Devices to Test Computer: The communication interfaces of test devices are connected to the test computer

- ITA: Custom design box that ease the connection between DUT and test devices especially designed for the DUT.

- Software: The drivers are used for each communication interface of test device to prepare test scenario.

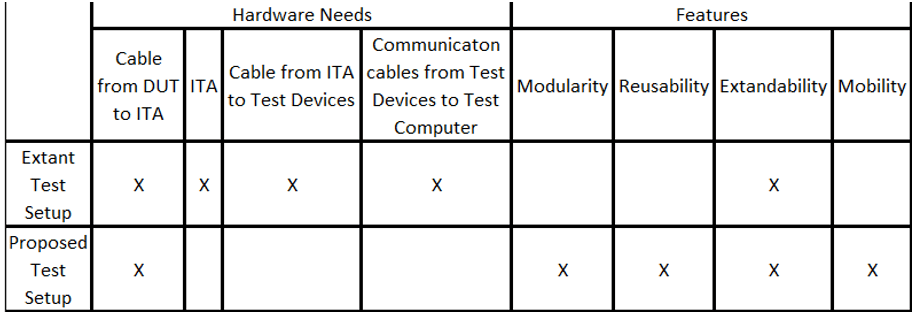

The needs and the software design time are reduced dirastically with the proposed test setup.

Furthermore; the advantages of the proposed test setup can be listed as:

- Test setup time to switch between one DUT to another is reduced because of no need to

- Change the whole cable assemblies, only one

- Rearrange communication settings between test devices and test computer

- The reduction in cost and error rate by preparing a cable structure rather than a complex structure (cables, ITA) as shown in Figure 5.

Figure 5-Complexity Difference Between Extant and Proposed Test Setups

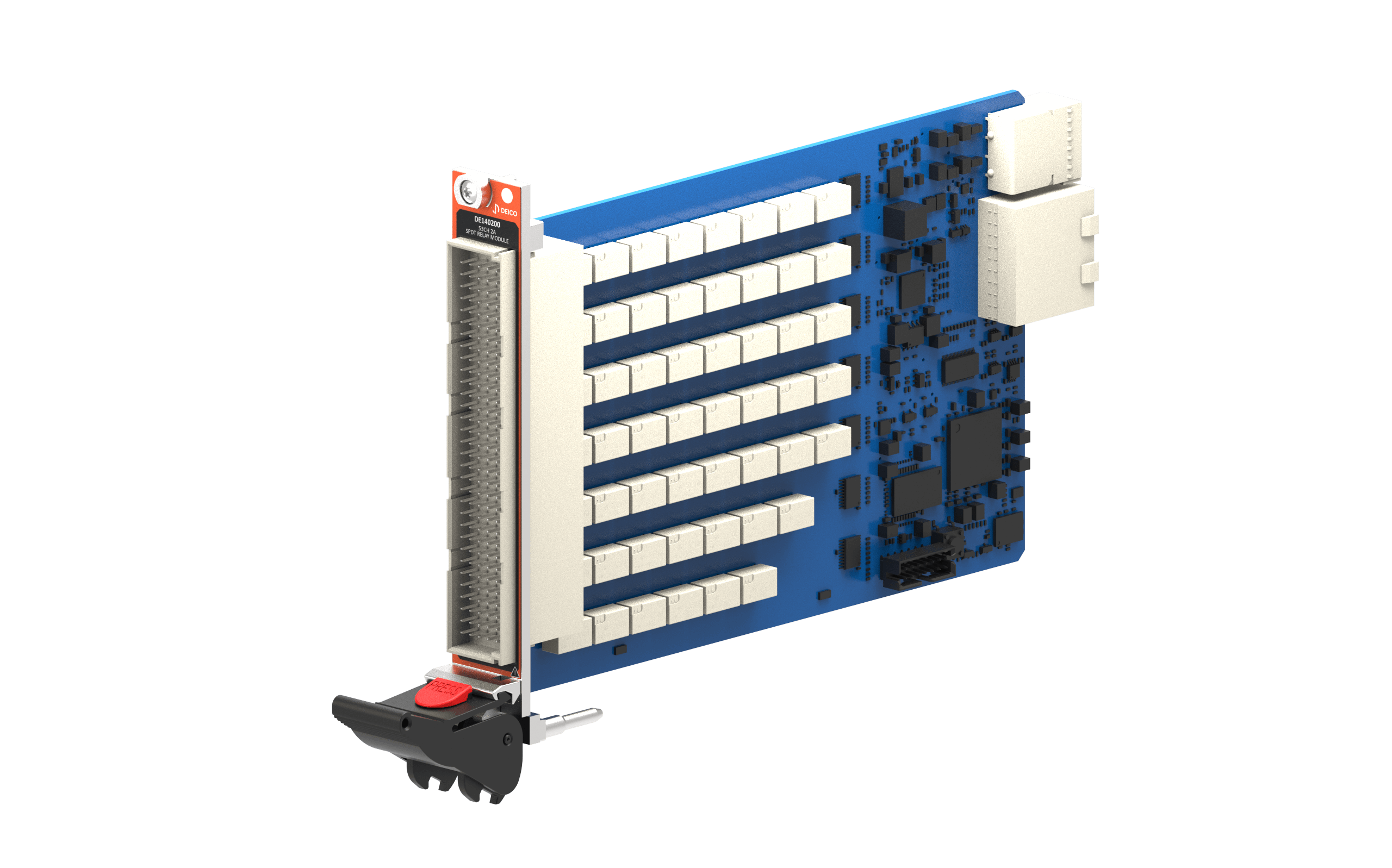

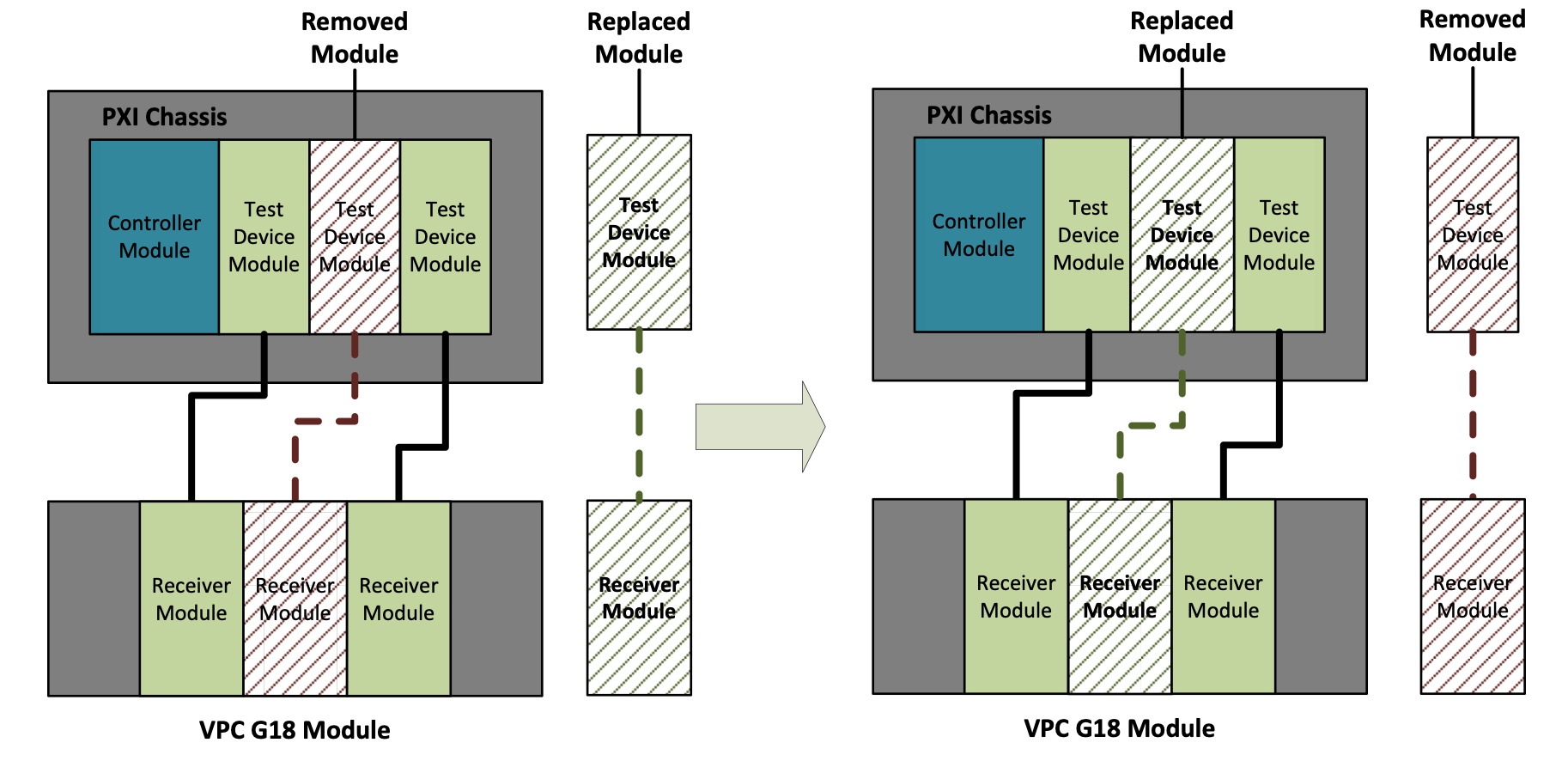

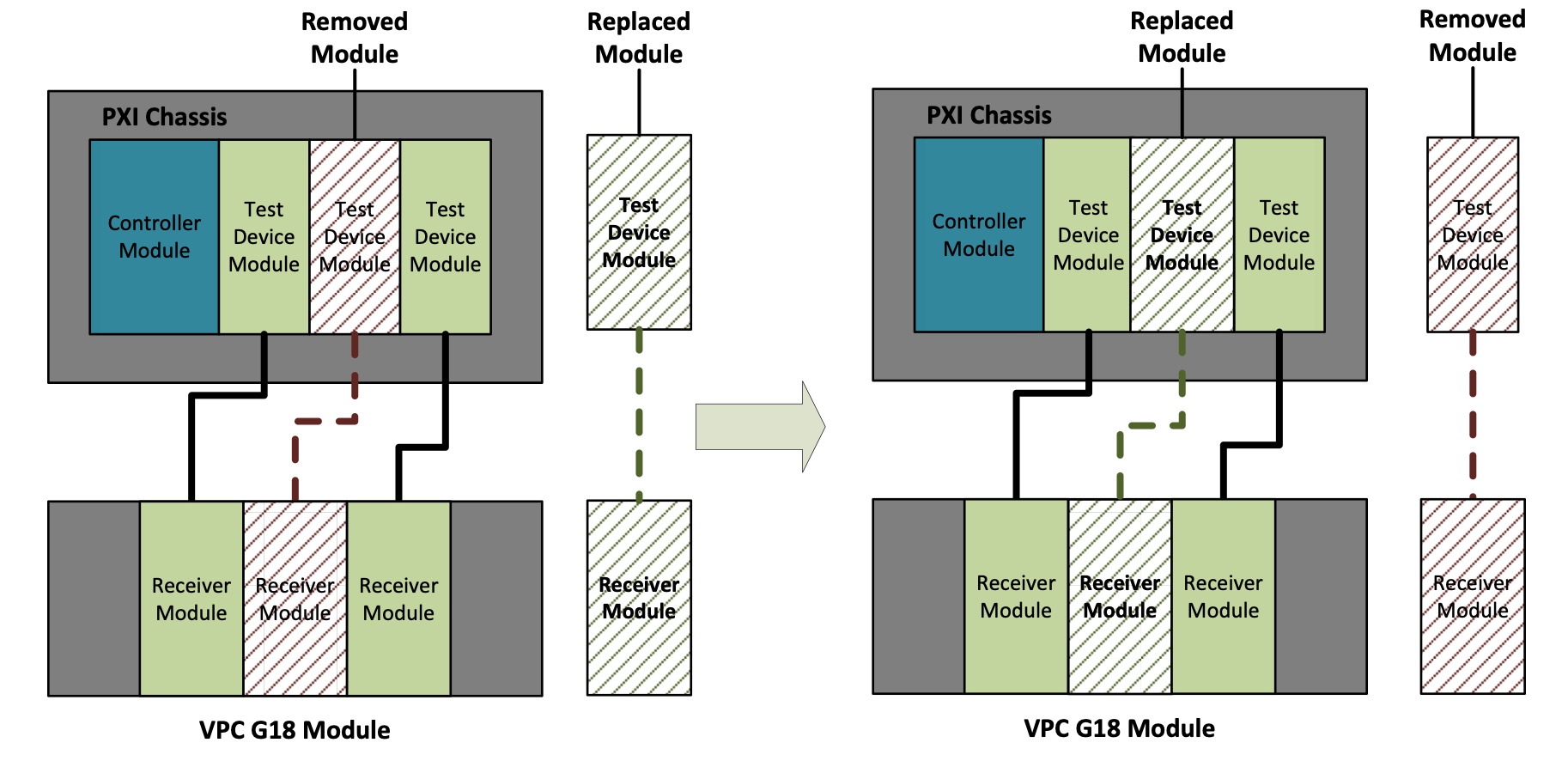

- By the help of PXI system, test setup can be reconfigured easily as shown in Figure 6.

Figure 6-Reconfigurable Structure

- The test setup mobility is increased. The mobility feature becomes crucial when the environmental and EMI/EMC tests are under considerations.

The differences between the extant and proposed test setups are huge when the comparison is made by the above explanations. The difference summary can be shown in Figure 7.

Figure 7-General Comparison Between Extant and Proposed Test Setup

5. CONCLUSIONS AND FUTURE WORK

A generic, modular, reusable, extendible test configuration using PXI connectivity and a test system based on this test configuration is proposed. The advantages and improvements coming with this configuration are mentioned. An example application of this test configuration and test system is described with their architecture, hardware, software and test methodology features.

REFERENCES

[1] Rehani, M.; Abercrombie, D.; Madge, R.; Teisher, J.; Saw, J.; “ATE Data Collection - A comprehensive requirements proposal to maximize ROI of test”, in ITC International Test Conference, 2004.

[2] Alves, V.; Borba , P.; “Distributed Adapters Pattern: A Design Pattern for Object-Oriented Distributed Applications”, in First Latin American Conference on Pattern Languages Programming, Rio de Janerio, 2001.

[3] Gajski, D., D.; Vahid, F.; “Specification and Design of Embedded Hardware & Software Systems”, in IEEE Design & Test of Computers, 1995.

[4] Han, Q.; Gutierrez-Nolasco, S.; Venkatasubramanian, N.; “Reflective Middleware for Integrating Network Monitoring with Adaptive Object Messaging”, in IEEE Network, 2003.

[5] Testing Ultra-Precise, Strategic-Grade Instrumentation Using a Flexible and Modular Common Test Station Architecture, 2014 IEEE AUTOTEST

[6] http://www.vpc.com/images/exploded/G18_slide_exploded_view_big.jpg