To many, a MIL-STD-1553 Bus Coupler is just a connector box or a component on a BOM list. But for a Systems Integration Engineer, this component is critical for the physical layer stability of the network.

At DEICO, we produce these couplers in three different forms: the DE8100 (PCB), DE8200 (Box), and DE8300 (In-Line) series. While they look different on the outside, the internal engineering relies on the same physics.

Here is a breakdown of what happens inside these components and why the specs matter.

The Internals: Physics of the Circuit

Regardless of the form factor-whether it’s a rugged box or a PCB module-the internal circuit performs two main jobs: Impedance matching and fault isolation.

The Transformer: Understanding the 1:1.41 Ratio

If you check our datasheets (DE8100, DE8200, DE8300) you will see a turns ratio of 1:1.41. This is a specific requirement, not a random number.

It comes down to impedance transformation. Impedance across a transformer changes proportional to the square of the turns ratio (N²). Since 1.41 is approximately √2, squaring it gives us 2.

What this means for your system: the transformer makes the impedance of your device (Remote Terminal) appear two times higher from the perspective of the main bus. This higher impedance reduces the load on the bus line. This allows you to connect multiple devices to the same network without degrading the signal quality.

The Resistors: Why 59 Ohms?

You will also see 59 Ohm ±1% 1 W resistors wired in series. The MIL-STD-1553B standard states that isolation resistance must be 75% of the cable’s characteristic impedance (Z₀).

- Standard Twinax cable is 78 Ohms

- 0.75 x 78 = 58.5 Ohms

- The closest standard resistor value is 59 Ohms.

The practical function: these resistors act as fault isolators. If a short circuit happens in a stub cable or inside a device (LRU), these resistors limit the current draw. This prevents the short from bringing down the entire main bus. The faulty device drops off, but the rest of the network keeps communicating.

Form Factors: Choosing the Right Type

While the internal circuit is standard, the mechanical packaging depends entirely on your platform’s constraints.

PCB Type (DE8100 Series)

Best for: custom mission computers, embedded systems. If you are designing the electronics inside an LRU, you don’t want an external box. The DE8100 series is an open-frame module that mounts directly onto your circuit board. It puts the 1553 interface right on the motherboard, saving weight and eliminating external patch cables.

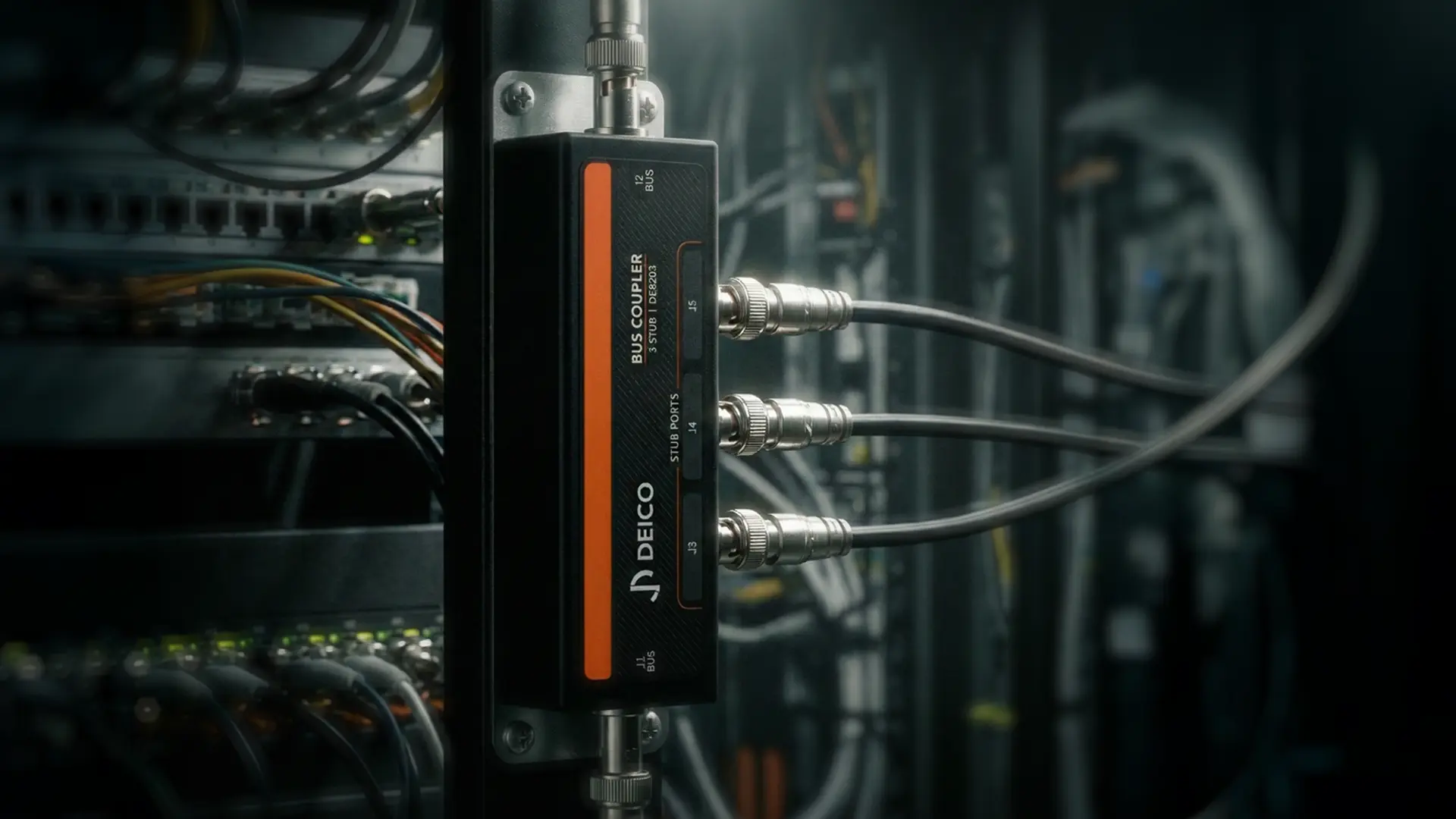

Box Type (DE8200 Series)

Best for: System Integration Labs (SIL), test benches, maintenance bays. This is the standard rugged solution. We use a 2 mm aluminum enclosure with a conductive white chromate finish. We use chromate instead of anodizing because it is conductive. This allows the enclosure to act as a Faraday Cage, grounding the cable shields to the chassis to block EMI (Electromagnetic Interference).

In-Line Type (DE8300 Series)

Best for: UAVs, satellites, aircraft cable harnesses. When you have tight weight limits or no space for mounting boxes, the in-line type is the solution. It uses a 0.5 mm tin-plated steel housing. The tin plating allows technicians to solder the cable shield 360 degrees around the housing. This creates a fully sealed, lightweight node that can be tied directly into the cable bundle.

Summary

Designing a reliable 1553 network starts with the physical layer.

- DE8100 PCB Type Bus Couplers: for embedding inside the hardware.

- DE8200 Box Type Bus Couplers: for external mounting and accessibility.

- DE8300 In-Line Type Bus Couplers: for minimum weight and integrated harnesses.

Check the DEICO MIL-STD-1553 Bus Couplers to find the configuration (number of stubs and termination style) that fits your specific topology.